Is the dual clutch a panacea? Demystifying Volkswagen gearbox technology

[Original by Aika Automotive Technology Channel]

Dual clutch gearbox, a once controversial but booming species. Twenty years ago, the dual-clutch gearbox was a rare animal. At that time, it was mainly used in the field of racing, which was far from consumers. Today, dual clutch has become a force that can not be ignored in the field of automatic transmission, and more and more new cars have begun to join this camp. In the process of popularization of dual-clutch gearbox, Volkswagen is an important promoter and practitioner, and many people’s cognition of dual-clutch begins with the letter "DSG".

Looking AT the product line of Volkswagen Group in China, it is not difficult to find that the dual clutch has occupied more than half of the country, and the limelight has far overshadowed AT or CVT gearboxes. At the media communication meeting held a few days ago, Aika Automobile communicated with the staff of Volkswagen College, discussed the development history and product layout of Volkswagen dual clutch technology, and obtained the latest news of electrified gearbox.

Volkswagen dual clutch family

The history of dual clutch gearbox can be traced back to the first half of last century. In 1939, Adolphe Kégresse, a Frenchman, put forward the technical concept of dual clutch, but the pessimistic economic environment at that time hindered the implementation of this idea. Rudolph Franke, a German, was the first to apply for the patent of dual-clutch gearbox in 1940, and carried out experiments on trucks, but it was not put into mass production in the end. It was not until the 1980s that the dual clutch gearbox emerged in the field of racing and entered the mass production considerations of some car companies. The large-scale promotion of dual clutch should start from the beginning of this century, and the contribution made by Volkswagen Group can never be ignored.

In the late 1990s, Volkswagen began to cooperate with Borg Warner on the mass production of dual-clutch gearboxes. In 2002, Volkswagen launched its first production car Golf R32 equipped with dual-clutch gearbox, and the Audi TT 3.2L model equipped with the same powertrain also went to the market the following year. Subsequently, Volkswagen gradually covered the dual clutch to golf, Touran and other models, and began to promote it on a large scale in 2007.

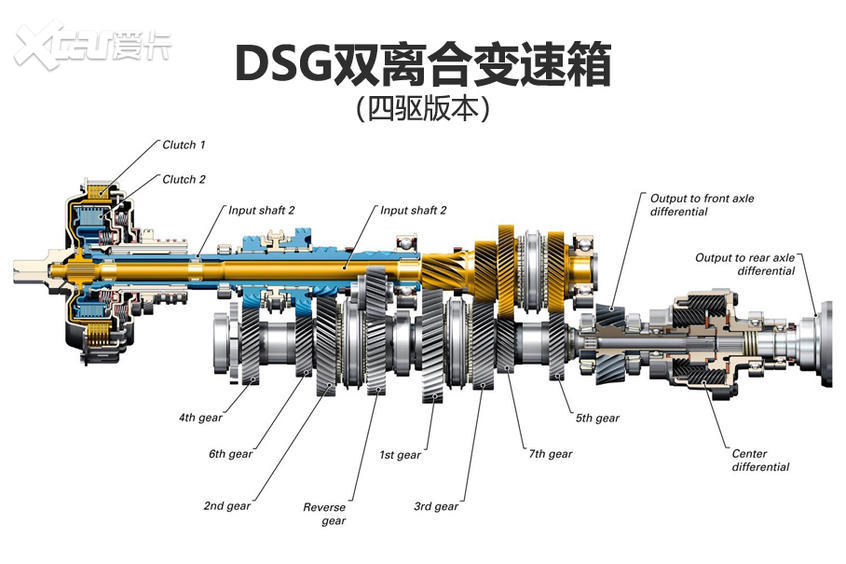

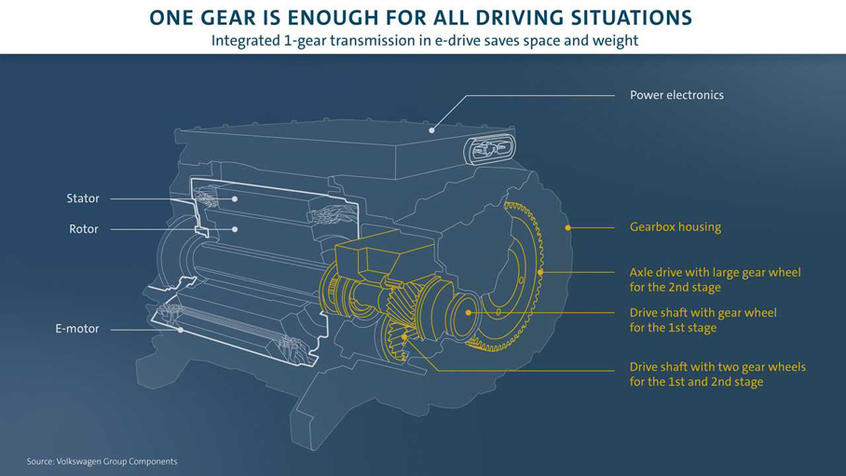

The original intention of the development of dual clutch gearbox is to combine the high efficiency of manual gearbox with the convenience of automatic gearbox. In order to achieve this goal, the dual-clutch gearbox adopts a similar mechanical structure to that of a manual gearbox, and realizes rapid shift connection through two clutches. At present, the dual clutch gearbox has appeared in most models of Volkswagen Group in China. Volkswagen brand calls it DSG direct shift gearbox, while Audi brand names it S tronic.

Among the above gearboxes, DQ200 is the only one with dry clutch. Although the torque limit of DQ200 is not high, it is enough to meet the needs of small-displacement turbocharged engines. Almost all the transverse 1.2T and 1.4T models of Volkswagen Group are using this gearbox. As the originator of DSG mass production, DQ250 was gradually eliminated and replaced by a 7-speed gearbox that paid more attention to fuel economy. DL series vertical dual clutch gearboxes are more common in Audi models, among which DL382 and DL501 are relatively common, while DL800 is a "high-end product" for sports cars with mid-engines.

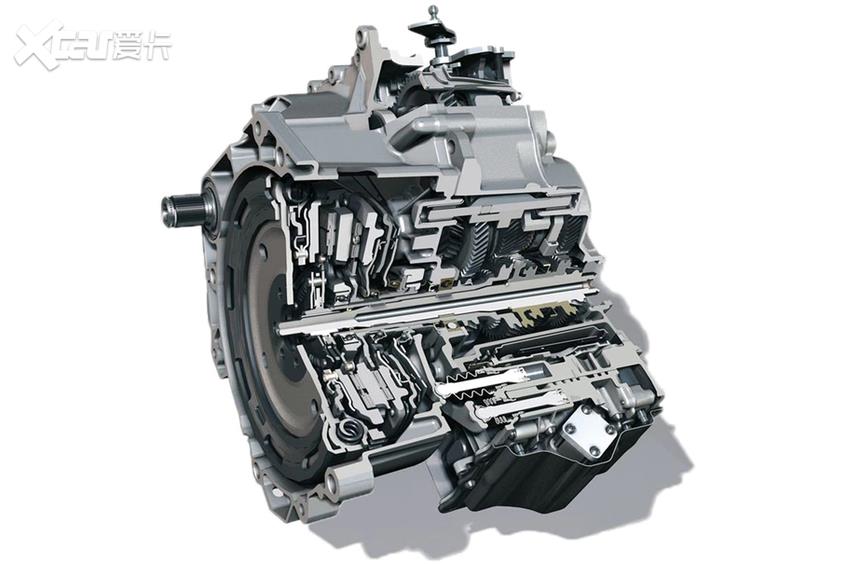

Evolution from DQ380 to DQ381

If DQ200 is an excellent partner of EA211, then DQ380/DQ381 is a tacit partner of EA888. Since entering the era of EA888 Gen3, Volkswagen has used DQ380/DQ381 7-speed dual-clutch gearbox to replace DQ250 6-speed dual-clutch gearbox on a large scale in China, and soon the European market has followed suit. Both the front and rear gearboxes adopt wet clutches, and the main purpose of increasing gears is to improve fuel economy and cope with increasingly stringent emission regulations.

DQ381 has taken a series of measures to reduce friction loss. The drive shaft and differential are equipped with low-friction bearings, and low-friction oil seals and low-viscosity transmission oil are used. DQ380 and DQ500 use mechanical gearbox oil pump, which consumes a lot of energy and cannot provide oil pressure continuously when the engine is stopped. DQ381 is equipped with mechanical oil pump and electronic oil pump at the same time, which reduces energy consumption on the one hand and improves the application scope and comfort of start-stop system on the other. Of course, TCU logic has also been upgraded, which is closer to consumers’ usage habits.

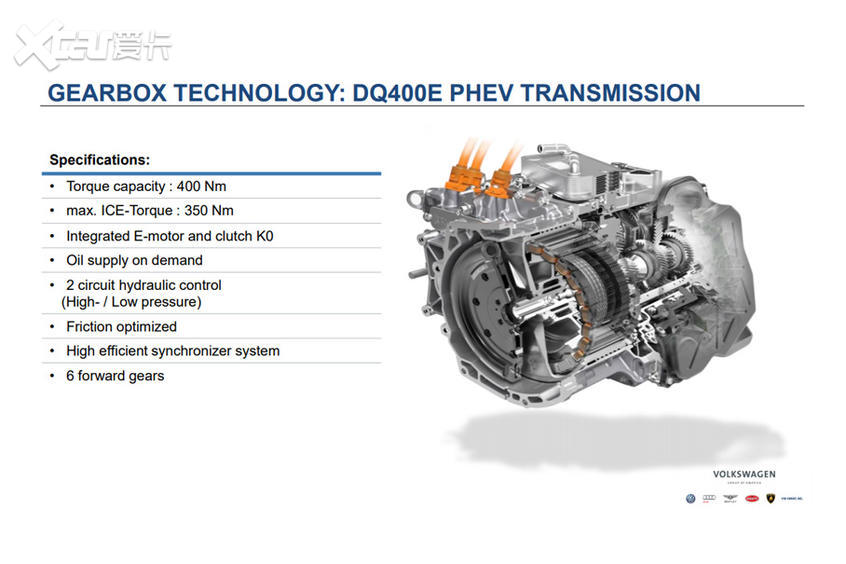

Analysis of electrified gearbox

In the mass product matrix, electrified gearboxes are divided into two camps: hybrid and pure electric. In China market, Volkswagen’s plug-in hybrid (PHEV) vehicles only use hybrid dual-clutch gearbox, while 48V light hybrid vehicles still use traditional dual-clutch gearbox. The DQ400e hybrid dual clutch gearbox adopts wet structure, which can bear the comprehensive torque of 400Nm, which is suitable for the high torque characteristics of PHEV system.

Compared with the traditional dual-clutch gearbox, the core change of DQ400e is the addition of motor and its related components. Because the motor is added to one side of the input shaft, the length of the DQ400e gearbox is increased, which increases the difficulty of spatial arrangement of the transverse power system. In order to control the size of the gearbox, the engineer sacrificed the seventh gear and adopted the sixth gear scheme. DQ400e is equipped with plug-in products such as Magotan GTE, Tanyue GTE and Tiguan L PHEV. With the promotion of Volkswagen electrification strategy, this gearbox will appear in more models.

Volkswagen is not a leader in the field of pure electric vehicles (BEV), but the menacing MEB platform still puts great pressure on many competing products. It is expected that by the end of this year, the ID brand products based on MEB platform will be made in China, and the new car will use APP310 power motor. The author was lucky enough to see the APP310 in kind at the communication meeting, but due to confidentiality reasons, I can’t show pictures to readers for the time being. It can be revealed that APP310 not only can provide stronger power output, but also has a more exquisite structural design, and the thickness of its electronic control device is reduced by more than half compared with APP290.

Editor’s comment:The development of dual clutch in China was not smooth sailing, and various stories made it controversial, but the market finally proved the existence value of dual clutch. Today, environmental protection is becoming more and more important, and the dual clutch has also derived a hybrid version, which is compatible with the motor with a compact structure. The future will eventually belong to a single-speed gearbox, and the exquisite APP310 makes people have unlimited expectations for the electric age of Volkswagen.

Wonderful content review:

Power is better than overseas version of Volkswagen 1.5TSI domestic preview

Not only a makeover, but also an analysis of the new BMW 5 Series /6 Series GT.

Who do you choose for Japanese brands? Prospect of hybrid new cars at various price points