State Regulation for Market Regulation: 25% Power Bank Spot Check Quality Unqualified

Mobile power banks are also called power banks. Due to their small size and easy portability, they have solved the problem of charging mobile phones and other electronic products anytime and anywhere. In recent years, sales have been very impressive. The latest national supervision and spot inspection results of mobile power supplies released by the State Regulation for Market Regulation show that a quarter of the products in the spot inspection failed, and the problems found were mainly due to various hidden dangers such as leakage and fire.

25% of the mobile power supply quality failed the national supervision and random inspection

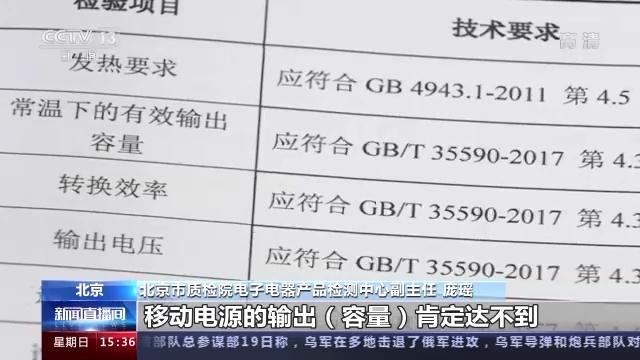

Miao Yuchen, Director of the Product Spot Inspection Department of the Quality Supervision Department of the State Administration for Market Regulation: This time, 108 batches of mobile power supply products produced by 107 enterprises in 9 provinces (cities) were randomly checked, and 27 batches of products were found to be unqualified, and the unqualified discovery rate was 25%. The inspection focused on 16 items such as the conversion efficiency, heat generation requirements, and radio disturbance of the products. After inspection, the unqualified items were concentrated on 5 items: conversion efficiency, effective output capacity at room temperature, heat abuse, overcharging, and radio disturbance.

Mobile power, also known as power bank, is a non-stationary charging product assembled from battery packs, circuits and casings. It is understood that there are more than 900 million smartphone users in our country in 2020; and according to relevant industry statistics, in 2019, our country’s mobile power output is also close to 900 million.

However, at the same time, the reporter’s investigation found that in recent years, with the increasing use of mobile power sources, fire and explosion accidents related to mobile power sources are also common in various places.

In December 2021, the mobile power supply in the home of Mr. Liu, a consumer in Guiyang, Guizhou, suddenly exploded while charging.

Consumer Mr. Liu: The power bank was charged for one night, but I forgot to unplug it when I sent my child to read the next morning. In the afternoon, it was charged and ignited.

After searching, the reporter found that on a bus in Guangzhou, the power bank in a middle school student’s schoolbag suddenly caught fire, causing thick smoke to spread throughout the carriage.

In recent years, there have been a number of mobile power fires in crowded places such as university dormitories, cabins, office buildings, and subways, threatening consumers’ personal and property safety.

Since the implementation of the national standard for mobile power supplies in 2019, the State Administration for Market Regulation has conducted national supervision and spot checks on such products for three consecutive years.

Pang Yao, Deputy Director of the Electronic and Electrical Products Testing Center of Beijing Quality Inspection InstituteFirst of all, national supervision and spot checks must place greater emphasis on safety items, because safety items involve consumers’ personal health and property safety.

The testing engineer told the reporter that if the mobile power supply safety project fails, it indicates that the product is at risk of overheating, fire, explosion, etc., and there are serious safety hazards.

8 batches of overcharging fail the test, which can cause fire and explosion

The reporter learned that it generally takes a few hours or even longer for the power bank to be fully charged. If you forget to unplug the power supply, you may even charge it all day and night. This situation is called overcharging. This requires that the internal quality of the power bank must be reliable, so as not to have safety hazards such as fire and explosion in the overcharged state. The State Administration of Market Supervision found that 8 batches of mobile power supplies failed the overcharging test.

During the investigation, the reporter learned that the mobile power supplies currently sold on the market are generally not equipped with adapters. Consumers mostly use adapters from other electronic products when charging the mobile power supply. The testing engineer told the reporter that if the adapter does not match the current parameters of the mobile power supply, the internal circuit of the long-term charging mobile power supply may be damaged. This requires that the internal battery pack of the mobile power supply is of reliable quality. In the case of failure of the protection circuit, it can still work normally without causing safety hazards to consumers. Overcharging items are a key safety indicator for testing the quality of the internal battery pack of a mobile power supply.

Beijing Quality Inspection Institute, Electronic and Electrical Products Testing Center, Yang Jiaju: The overcharging project is to assess whether there is a risk of fire or explosion when the internal battery is continuously charged with overvoltage and overcurrent when the protection function of the mobile power supply fails. A total of 8 batches of mobile power overcharging projects were unqualified in this national pumping. Failure to overcharge may lead to fire and explosion in the mobile power supply, threatening the safety of consumers’ personal and property.

During the over-charging test, eight batches of mobile power supplies were judged to be unqualified, and the unqualified products were produced by companies such as Shenzhen Harman Technology Co., Ltd., Shenzhen Baojia Energy Co., Ltd., and Shenzhen Yimi Technology Co., Ltd.

9 batches of hot abuse failed the test, and there are hidden dangers such as explosion

The reporter noticed that this time, 9 batches of mobile power supplies that failed the 15 batches of safety projects were unqualified for thermal abuse, and this project was also the project with the most unqualified products.

In the testing laboratory, the reporter saw that the inspectors first disassembled the battery pack inside the mobile power supply, and then put it into the test chamber. When the temperature reached 130 degrees Celsius, the battery was kept at a constant temperature for 30 minutes. During the process, the battery did not catch fire or explode, and the heat abuse items were qualified.

The battery of this mobile power bank began to bulge 6 minutes after the start of the test, began to smoke 20 minutes later, and then the battery caught fire and exploded. The huge airflow generated by the explosion could be seen exploding the ventilation equipment of the test chamber.

Beijing Quality Inspection Institute, Electronic and Electrical Products Testing Center, Yang JiajuThe thermal abuse project assesses the ability of the internal battery of the mobile power supply to withstand high temperature. If the mobile power supply encounters a high temperature environment during use, it may cause a fire and explosion, which poses certain safety hazards. For example, the temperature in the car will be particularly high in summer. If the mobile power supply is kept in the car, its environment is a high temperature environment.

A total of 9 batches of mobile power supplies, including this batch of products, caught fire or exploded during the thermal abuse test, and were judged to be unqualified. The nominal production units of the unqualified products were Shenzhen Fushun Cheng Technology Co., Ltd., Dongguan Beisest New Energy Technology Co., Ltd., Shenzhen Shisailai Technology Co., Ltd., and other 9 enterprises.

9 batches of virtual standard capacity cannot meet the charging requirements

During the investigation, the reporter learned that mobile power supplies are generally marked with "rated capacity" to indicate how much power the product can provide for electronic products such as mobile phones. This time, the national pumping found that some mobile power supplies have quality problems with false rated capacity.

The rated capacity claimed by the manufacturer of this product is 4000 mAh, and the measured output capacity is 2160 mAh, which is only more than half of the nominal value. It is the most serious product with the rated capacity false standard found in this national pumping.

Qi Rui, Electronic and Electrical Products Testing Center, Beijing Quality Inspection InstituteIn layman’s terms, the higher the effective output capacity of a product at room temperature, the more it can charge electronic devices such as mobile phones. If you use this mobile power supply to charge a mobile phone with a battery capacity of 4,000 mAh, the mobile power supply may run out of power before the mobile phone is fully charged.

The testing engineer told reporters that, in general, the larger the rated capacity of the mobile power supply, the more expensive the price will be. If the enterprise falsely labels the capacity, consumers will spend more money to buy products that do not live up to their name, and their economic benefits will also be damaged.

Some of these products are deliberately falsified by the manufacturer in order to raise the selling price, and some products are actually labeled on the outer packaging as the capacity of the internal battery cell, not the actual output capacity. Some enterprises with low manufacturing level are unwilling to indicate the true rated capacity due to low conversion efficiency.

Pang Yao, Deputy Director of the Electronic and Electrical Products Testing Center of Beijing Quality Inspection Institute: Now there are some products that do not have a rated capacity. It is marked with capacity or battery capacity. It is not ruled out that these refer to the capacity of the battery or battery pack, not the capacity that the mobile power supply can output externally. If the nominal is battery capacity, the output (capacity) of the mobile power supply will definitely not meet the nominal capacity requirements.

After testing, 9 batches of mobile power supplies failed to meet the requirements for their effective output capacity at room temperature. They were mobile power supplies produced by nominal production units such as Di Fu Le Bio (Shanghai) Co., Ltd., Guangzhou Jianghai Technology Co., Ltd., and Shenzhen Shi Sailai Technology Co., Ltd.