Looking at Zhu Jiangming running at zero distance, thinking of the boatman in the distance.

"I am an engineer myself. I have done both hardware and software. Therefore, our zero run will definitely have the culture of engineers. " The founder of Zero Run once said this.

The Science and Technology Man Created by The Big Bang Theory

Zhu Jiangming and his zero-run car really have a "science and technology man" temperament. Everything is "technology is king" and independent research and development are highly respected. Judging from the S01, the first mass production car with zero running, all the core components should be self-researched, and there is already the strength of "no madness and no survival".

The industry is not the first to build such a "science man". Nowadays, the zero-running car is very much like the first electric car enterprise in China. Zhu Jiangming’s engineer temperament is also reminiscent (known as "the boatman").

BYD started its electric layout at the end of its own brand, and it caught up with the best time of electric car in China. Soon after the zero-run car started, can the running method of "self-research"+"self-construction" still win?

The tactics of technical men: super learning ability

Zhu Jiangming, founder of Zero Run Car, and Wang Chuanfu, president of BYD Co., Ltd.

"We started with the enterprise dispatching machine in 1993 and transformed the security equipment in 2001. We have experienced two successful entrepreneurial processes from 0 to 1." Zhu Jiangming recalled and said.

In 1993, 26-year-old Zhu Jiangming and Fu Liquan, the current chairman of Dahua Co., Ltd., pooled 5,000 yuan to set up Dahua in a primary school in Hangzhou and started their business. Zhu Jiangming, who graduated from Zhejiang University majoring in telecommunications, is good at embedded algorithm and chip-level combination of software and hardware at the bottom of the computer, and Dahua originally used this embedded technology for enterprise dispatching machines.

In 2001, Dahua’s main business turned to security, which made Zhu Jiangming completely a layman. By studying and studying, Zhu Jiangming led the team to develop 8-channel embedded DVR in 2002. This technical breakthrough in the security industry has enabled Dahua to enter a period of rapid development, laying a foundation for the future development of Dahua.

Zhu Jiangming, who once couldn’t tell all the camera parameters, became an expert in video security technology. HDCVI (high definition composite video interface) video transmission technology invented by Zhu Jiangming was officially released by Dahua in 2012, which triggered a technical earthquake in the field of video transmission.

As a coaxial high-definition transmission technology, HDCVI can realize the transmission of megapixel video over 500 meters, breaking through the bottleneck of resolution of traditional analog technology. In 2013, the international HDcctv Alliance announced the acceptance of HDCVI as an international standard, and HDCVI technology became the first technical specification in China security industry to be included in the international standard. In December 2014, HDCVI technology and standards were included in GA/T1211-2014 "Technical Requirements for Security and Prevention of HD Video Surveillance System".

With the invention of HDCVI alone, Zhu Jiangming opened the door to wealth and freedom. "Every year, relying on HDCVI, Zhu Jiangming can receive a lot of patent fees from all over the world." Insiders said. However, Zhu Jiangming is still not satisfied. In 2015, he decided to create a zero-running car and wanted to realize the third "0 to 1" change in his life.

Boatman: You can make everything yourself.

Wang Chuanfu, a fellow science and engineering man, is one year older than Zhu Jiangming. The advanced story of "Brother Boatman" has long been a household name in China. Comparing the two, "science and engineering men" seem to like to do the challenge of "nothing can be done".

Wang Chuanfu likes to manage enterprises by means of management technology. "Technology is king and innovation is the foundation" is the fundamental development concept of BYD put forward by Wang Chuanfu. Wang Chuanfu does not impose restrictions on BYD. He thinks that everything can be made by himself, and what is made is more useful than what is bought at a high price. He thinks that technology patents are all’ paper tigers’. The remarks that "20 engineers support a mechanical arm" and "cars are just a pile of steel" make "science man" Wang Chuanfu look simple, arbitrary and conceited. He enthusiastically pursues technological innovation. He uses strong creativity and indigenous methods to break the technical blockade. He despises unreasonable business order and game rules. His growth mode is simple and direct: if you don’t help me, I will do it myself.

In 2003, BYD produced more lithium batteries than Sanyo, Sony and Panasonic, accounting for 60% of the global market. At that time, Japanese companies had established a highly automated battery production line, and the mechanical arm could replace a lot of labor. When representatives of Japanese enterprises visited BYD, they were amazed at the production efficiency of BYD’s semi-automatic+manual "human sea tactics". In that crazy era, Wang Chuanfu made full use of domestic low-cost human resources to subvert the monopoly position of Japanese battery industry at that time.

In 2003, BYD began to transform into the automobile industry. Wang Chuanfu’s decision inevitably met with some opposition. Wang Chuanfu said confidently, "I am determined to do it, and I believe it can be done. Judging from the road BYD has traveled, more than 98% of my decisions are correct! " "I will work as a car for the rest of my life!"

Shortly after purchasing Qinchuan Automobile, Wang Chuanfu asked his men to collect several boxes of books on automobile technology for him in bookstores in Xi ‘an and Beijing. When Wang Chuanfu invited car design expert Lian Yubo to join BYD, Lian Yubo asked, "Do you know anything about cars?"

Wang Chuanfu honestly replied, "I like cars. I have read hundreds of books."

At the beginning of BYD’s transformation, it was sung down by the capital market and its stock was badly sold. Wang Chuanfu once promised fund managers that entering the car "will bring the company 30 million profits and the production and sales of 30,000 cars one year later". As a matter of fact, in the first two years of BYD Auto, it only spent a lot of money to build a "Fleur" model.

BYD’s First Model-"Fowler"

"Fowler" is basically BYD’s "behind closed doors" product, and the dealers can’t laugh and cry when they look at the "four unlike" in front of them, so the sales volume will naturally not be ideal. In 2005, BYD’s annual report showed that BYD sold only 15,993 cars, with a loss of 91.3 million RMB.

How to build a good car in a short time? BYD adopts reverse research and development. The so-called reverse research and development is to disassemble mature cars, learn from the advantages of other people’s products and develop their own products in reverse. This is more time-saving than saving R&D funds from 0 R&D..

In 2005, BYD launched the first car that really opened the market for BYD-"F3". Even Wang Chuanfu was surprised. In 2006, Wang Chuanfu said, "The current hot sale is completely unexpected. At first, I thought it would be more satisfactory to sell 2,000 units a month. However, according to the current sales capacity, we can walk 10,000 units a month. " Why can "F3" succeed? Because F3 was almost a replica of the best-selling car Toyota Corolla at that time, and the price of F3 was only half of the former.

BYD F3, a replica of Toyota Corolla

Like making batteries, BYD has almost completely produced its own products from production line to automobile parts assembly. At that time, BYD workers said that except for glass and tires, everything on the car was made by BYD itself; It seems that BYD, who has only been in the business for two years, has accomplished an impossible task, which has greatly saved the manufacturing cost and formed a market advantage.

In 2006, BYD quickly launched F3e, an iron-lithium electric vehicle, based on F3 platform. The motor, reducer, battery components and control system of F3e are all developed and produced by BYD. Although the F3e electric vehicle was not successful at that time, it still showed Wang Chuanfu the advantages of electrification. BYD concentrated its R&D efforts on the research and development of its first-generation hybrid technology DM module. At this point, Wang Chuanfu began an all-round attack on fuel vehicles, electric vehicles and automobiles.

Today, BYD has almost become an all-round player. We can produce 2.0T in-cylinder direct injection, dual-clutch DM plug-in module that can be compared with Toyota Prius, and a three-electric technology platform including battery manufacturing, etc. In the "China Automobile Technology Development Report" released in December 2017, BYD’s patent technology is ranked first among mainland automobile enterprises.

Zero Run: Self-research+Self-creation

Can BYD’s "all self-produced" model still work today?

Lingpao Jinhua base welding workshop

"All car companies with a long history will eventually go to the road of" self-research "and" self-made ",and zero running is only the first to make the right choice." Zhu Jiangming said. Unlike the internet, zero running is low-key and crazy. In the 40 months since the establishment of Zero Run Automobile, we have carried out the values of "technology is king" of science and engineering men, and "the foundation for IT people to build cars-insisting on independent research and development of core technologies", which makes us seem to see the shadow of BYD in that year.

Independent research and development of automatic driving system

Different from BYD’s generation of car-making forces more than a decade ago, the focus of automobile development is on automobile mechanical technology. Vehicle design; Nowadays, the new trend of automobile electrification and intelligence has put forward new topics for the new generation of car makers.

"50%-60% of electric vehicles are actually related to electricity, and the composition of electricity is not necessarily less than that of machinery. The underlying technology will have a large number of electrical components to cooperate and interact. For the next generation of automotive hardware, especially the underlying electronic and electrical architecture technology, zero running based on Dahua technology background is completely advantageous. " Zhu Jiangming explained.

"Zero Run is the second vehicle manufacturer in the world with complete independent research and development capabilities for smart electric vehicles." Zhu Jiangming said confidently.

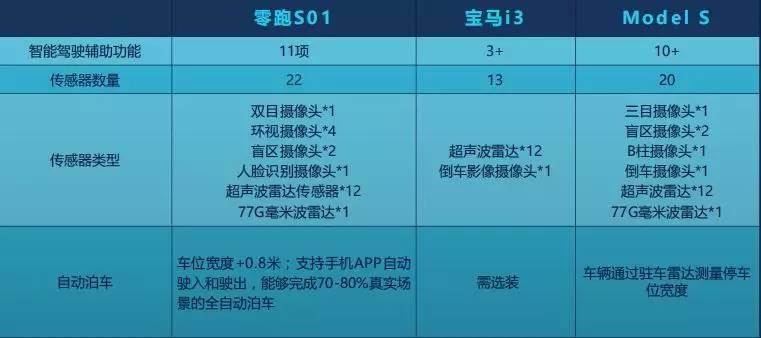

Different from the situation that other manufacturers rely on, Zero Run benefits from the technical advantages of Dahua Co., Ltd., and the cameras, sensors, AI autopilot chips, core software and algorithms involved in technology have been independently developed. At present, the zero-run car has achieved L2.5-level automatic driving, which can support L3-level remote upgrade. In 2020, it is planned that all models of zero-run cars will achieve L3 level through software upgrade, and in 2021, L4/L5 automatic driving test will be carried out in a small scale. After 2025, it will reach the L4/L5 level of mass production.

Comparison Table of Intelligent Driving Assist Function between Zero Run S01 and Competing Vehicles

What is the relationship between the chips in the lowest layer of intelligent vehicles? What is the embedded algorithm? Zhu Jiangming and Dahua, who have been dealing with electrical architecture technology for 20 years, have taken a fancy to the development opportunities of automobile intelligence and electrification, which is also the advantage of zero-running into the electric vehicle market. In addition, more importantly, the core technology of domestic intelligent networked automotive technology is missing, and Zero Run wants to fill the gap in automotive smart chips and intelligent algorithms. Zero-run car is jointly developing AI autopilot chip-Lingxin 01 with Dahua Co., Ltd. According to the relevant personnel of Zero Run, Lingxin 01 will have the ability of deep autonomous learning, and its computing power will reach the mainstream level in the industry, while supporting multi-chip flexible combination. At present, Lingxin 01 has entered the stage of integration verification, and it is expected to carry out real vehicle testing in the second quarter of next year.

Self-developed body platform

Different from BYD’s reverse research and development, Zero Run claimed that it had developed three body platforms-T-Platform, S-Platform and C-Platform from the beginning. The Zero Run S01 is the first mass production model based on S-Platform.

S01 is based on the design of electric vehicle platform, and the components of the whole vehicle, such as body, chassis, powertrain and battery pack, are all designed independently by zero-run. S01 curb weight is only 1240 kg, and the battery module accounts for 80% of the vehicle width. In this numerical performance, Tesla is 78%, while the average value of the electric vehicle industry is 60%. Its body-in-white weighs only 215 kg, accounting for 17% of the curb weight, while the average value of the body-in-white of electric vehicles is 20~25%.

Zero Run S01 Body-in-White

Platform S is designed with a toughened cage structure around the protection of the passenger compartment to ensure that the passenger compartment has sufficient rigidity and strength. The platform expansibility was also considered in the early stage of research and development, and the architecture can be extended from the current S01 two-door four-seat to five-door cars and models. S01 body-in-white roof adopts embracing laser welding technology to optimize the solder joints; The car body adopts a large number of processes such as thermoforming and rolling, and the proportion of thermoforming and high-strength steel is over 70%. Important anti-collision paths such as A-pillar /B-pillar/door anti-collision beam and front cabin are thermoformed, and the tensile strength reaches 1300Mpa;. The inner and outer doorsills are rolled, and the tensile strength reaches 1180Mpa.

Self-developed "Three Electricity" System

"Hercules" electric drive assembly

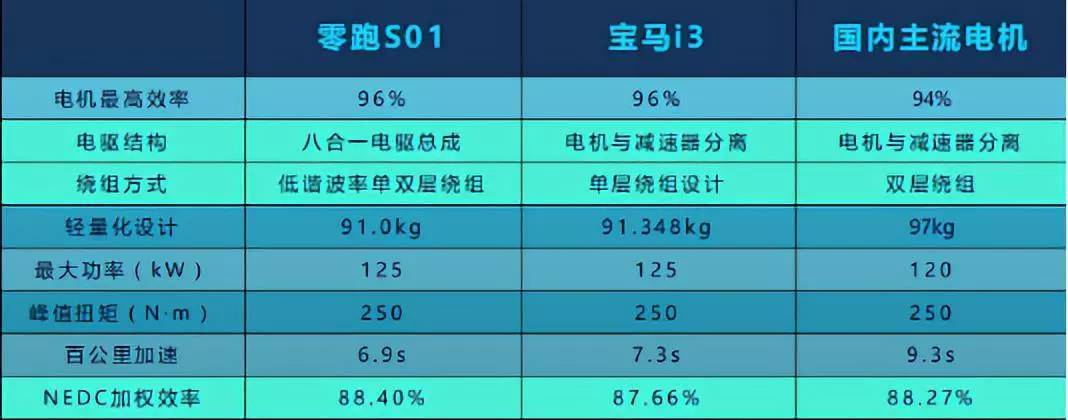

As the core three-electricity technology of electric vehicles, zero-running is all independently developed except batteries. Zero-run S01 electric drive is code-named "Hercules". Zero-run is fully developed forward, and the lightweight design scheme of "three in one" of motor, controller and reducer and "five in one" of motor controller is adopted.

Hercules is divided into an upper part and a lower part. The upper part is a "five-in-one" motor controller, which is divided into an upper case and a lower case.

Case) section. The upper box part is DCDC (vehicle power supply), MCU (motor controller) and PDU (high voltage distribution module), and the lower box part is VCU (vehicle controller) and OBC (on-board charger). The lower part is the driving motor and reducer. The upper part and the lower part are connected by a flexible fixed damping mechanism to form a "three-in-one" system.

This set of electric drive assembly has completed the accelerated life test of 500,000 kilometers, and it is also the first one in China to complete 120,000 continuous peak power start and peak power energy recovery braking cycle life tests. At present, it has mass production capacity. Compared with the traditional design with the same performance, "Hercules" reduces the weight by 30% and the volume by 40%, and the overall mass is only 91kg, but it still achieves the maximum power of 125kw and the peak torque of 250Nm; as the electric drive assembly. The highest efficiency of the system reaches 93.6%, and the high efficiency ratio exceeds BMW i3 by 94.49%.

Comparison Table of Motor Efficiency and Electric Control Parameters between Zero Run S01 and Competing Vehicles

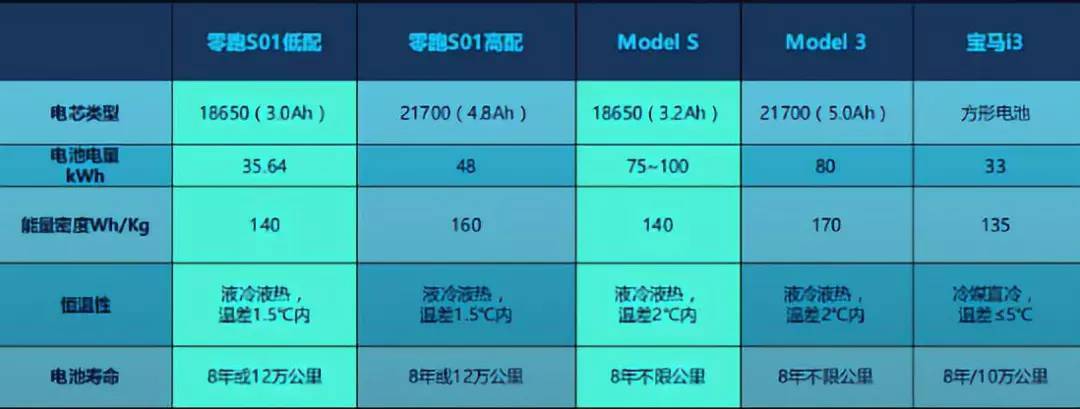

After the electric drive assembly, we are looking at the battery pack of S01. The power battery PACK of a zero-run car is all independently developed except the battery cells, which is "the highest degree of independent research and development of battery packs in domestic automakers except BYD, including modules, PACK, BMS hardware and software". Due to the integrated thermal management scheme of cold and heat, the charging and discharging efficiency of the system reaches 97.7%, and the discharging efficiency can still reach 92.5% in the area of -15 degrees. The four-in-one shunt is used for current detection, which makes the SOC accuracy reach 3%; Adopt single cell bipolar double insurance to reduce the risk of thermal runaway diffusion; The battery box shell adopts integrated aluminum casting process, which reduces the total weight of the box by 40%.

Comparison Table of Battery Pack Parameters between Zero Run S01 and Competing Vehicles

Although Zhu Jiangming thinks that Zero Run wants to be Huawei in the automobile industry, as far as the current measures of Zero Run are concerned, they are more like taking the old road of BYD. Zhu Jiangming may not be as fanatical as Wang Chuanfu, but the values of "science man" and "technology is king" will make them reach the same goal by different routes.

S01, the first production car with zero running.

Is it reliable for "science man" to build a car? Judging from the successful example of BYD, the hard-core ones are very reliable. However, it is not enough to drill only in technology. It is indispensable to do a good job in "humanity" and "feelings" of automobiles, and "science and technology men" also need to open their arms and embrace the world.

BYD’s success is not only due to its tireless innovation, cost reduction, hard battle, "reverse development", its ability to appeal to consumers, but also its necessity to open the market. In the past year or two, BYD’s "Dynasty Series" has sold well, not only because of the three-electric technology, 2.0T engine, dual-clutch gearbox and DM hybrid, but also because of Wolfgang’s dragon face. BYD has gone a long way from a technical expert to a product expert, and it is still on the road.

Nowadays, in terms of intelligence and electrification, traditional car companies at home and abroad have begun to display their technical reserves and launch wonderful products. It’s a long way to go to the technical master. Let’s see if he can beat his opponent. (End)