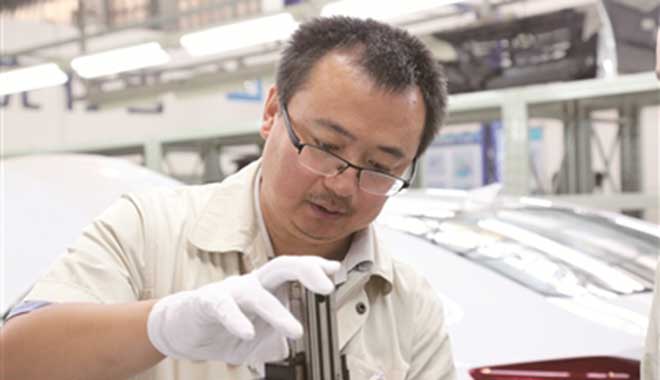

Wang Zhiwei: He solved the problem of baffling foreign automobile experts in two hours.

Zhiwei Wang

CCTV News:"A simple and beautiful" car dream "will always shine in my heart: it is because I love cars and Beijing cars that I have persisted for more than ten years, and I will continue to do it with my life." The man who said this is Wang Zhiwei, a senior technician in a Beijing automobile factory. Although he is only 37 years old, Wang Zhiwei already holds many titles, such as Beijing’s senior industrial technical expert, winner of the National May 1st Labor Medal, and "youth post expert" in the national automobile industry.

Wang Zhiwei, a native of Shunyi, Beijing, likes playing with machinery since he was a child. After graduating from junior high school, Wang Zhiwei was admitted to Beijing Automotive Industry School to study in a technical secondary school. After graduating from technical secondary school, he went to a car company in Beijing and worked in the assembly workshop.

Automobile assembly and adjustment workers need to assemble and debug tens of thousands of parts to ensure that every screw and every wire are accurate, so that the automobile can run normally. However, one of the wires is out of order, which is often difficult to detect. After years of exploration, Wang Zhiwei has summed up a set of unique vehicle circuit system adjustment and detection technology and troubleshooting methods, which can quickly detect and eliminate faults.

From a junior worker to a senior technician, the average person needs more than ten years, and he has completed five consecutive technical jumps in one competition. After the introduction of new models, he solved technical problems that foreign technical support experts could not solve, and he solved them in two hours.

"I work as an assembler on the production line. Go to work at 8 o’clock every morning and get off work at 8 o’clock or even 10 o’clock in the evening. The hardest thing is that in 2003, as an operator on the production line, I couldn’t see the future, and my thoughts fluctuated at that time. " Wang Zhiwei said.

However, the turnaround also occurred that year, and the production capacity of the car factory was expanded from 50,000 to 150,000. At this time, the workshop maintenance team recruits people, and the new team is responsible for maintaining the new car that has just rolled off the assembly line. It has high technical content and needs an exam to enter. Wang Zhiwei, 23, and hundreds of employees signed up for the exam, and finally won the top 6, and successfully entered the maintenance team.

Subsequently, Wang Zhiwei started the learning hegemony mode of day and night, and he held a large pile of circuit system adjustment detection methods and troubleshooting methods of various models, which became a "big hand" for everyone in the maintenance team.

Wang Zhiwei at work (right)

After obtaining the certificate of senior technician, Wang Zhiwei began to take apprentices. Newcomers are just graduates, without any experience, and need to be taught by hand. "I have a low education and I have to teach others, so I have to improve my theoretical study. Many times, I am learning and selling now." Wang Zhiwei said, "All say ‘ Church apprentice, starving master ’ But in my opinion, this is not a problem. When bringing new people, I will tell them which operations are correct and which are incorrect, where to start, and which level of knowledge to learn. "

In order to improve the professional quality of the whole staff in the workshop, Wang Zhiwei not only took full responsibility for the technical training of the assembly workshop, but also launched the "E2E Weekly Technical Promotion" for engineers to learn and improve, and the "Zhiwei Lecture Hall" for technical personnel training, which taught automobile theoretical knowledge and assembly skills, and trained more than 4,000 employees successively, and trained 7 skilled automobile electrical maintenance workers, of whom 25 grew up to be technicians under their guidance, and two became senior technicians.

One year, a certain model of the eighth generation could not be started after it was first rolled off the production line, and the technical support from South Korea could not solve the problem, so they called Wang Zhiwei to come over by name. After Wang Zhiwei went over, he used the unique vehicle circuit system to adjust the detection technology and troubleshooting methods, and solved the problem in two hours.

Since joining the work, Wang Zhiwei has solved more than 120 technical problems in production, including 27 outstanding innovations, 11 utility model patents and more than 300 production improvement projects.

In 2009, the company established the "Wang Zhiwei Chief Technician Studio" while continuously achieving various technological innovations. In the innovation studio, Wang Zhiwei mainly focuses on the improvement of tools and techniques, the cultivation of talents, the proposal of economic and technological innovation, and the improvement of achievements. Wang Zhiwei led the studio members to put forward more than 160 improvement measures in the company’s "two investments and one mention" project, saving nearly 7.4 million yuan.

After years of persistence and forging, "Wang Zhiwei Chief Technician Studio" has developed and trained a large number of outstanding young technicians. These young technicians have now become builders of various factories, and continue to influence and drive a new group of technical youth. (Source: Zhonggong. com)